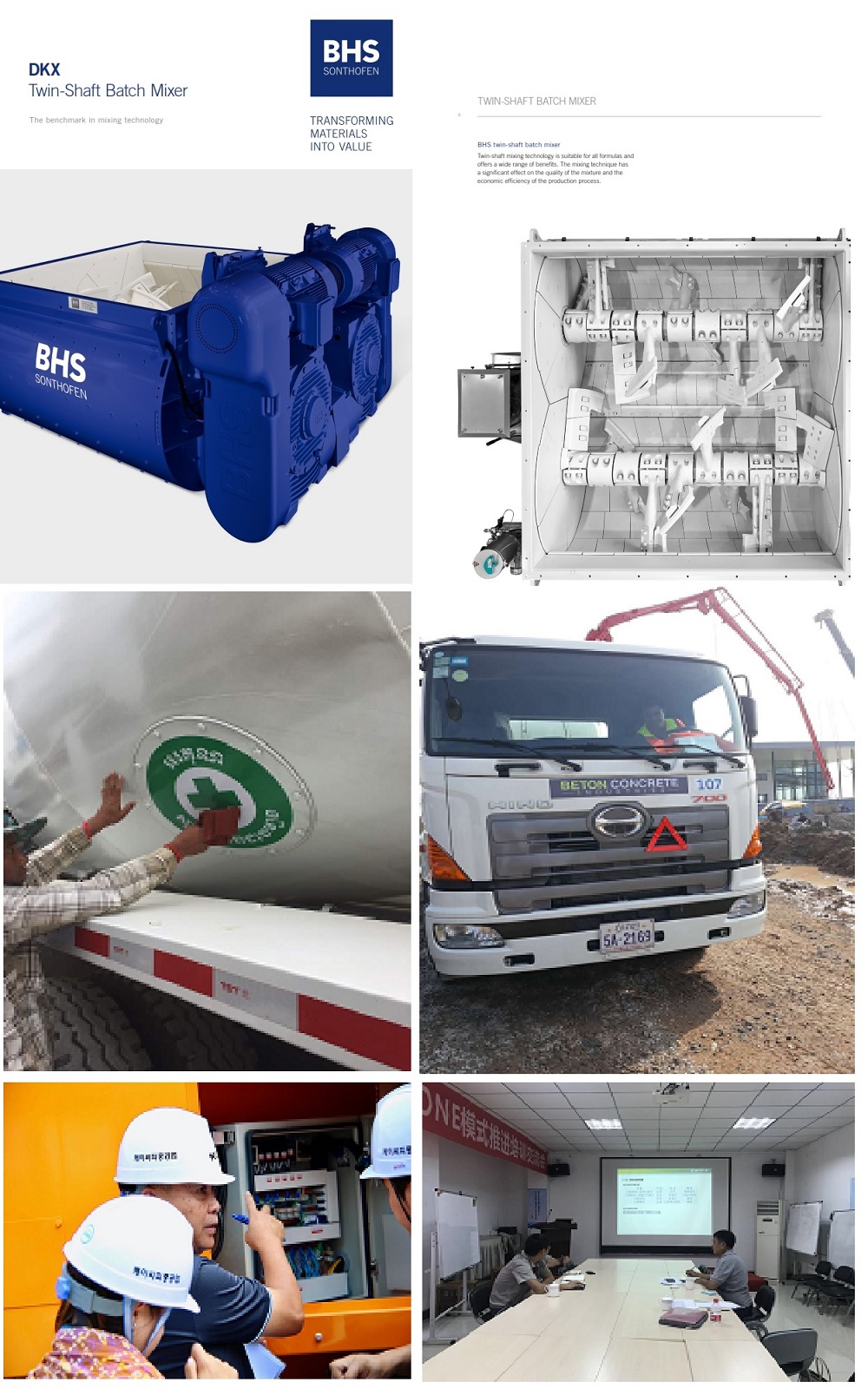

READY-MIXED CONCRETE

BETON CONCRETE INDUSTRIES is a Cambodian and Singaporean Experience established Partnership Company with committed to provide a wide range of ready-mix concrete with Stronger, Durability and Better Performance.

Beton Concrete Industries dedicates to establish a most quality assurance concrete producer industry.

Established in 2016 and commenced in 2017 at Phnom Penh, Cambodia, Beton Concrete Industries is a large scale and responsibility comprehensive concrete ready mix producer.

With the more than 30 year experience Engineers and Team, Beton Concrete at currently awarded the single largest concrete supply more than 100,000 cubic meter of concrete for the Ring Road National Three project.

Technology is the soul and research and development is the core ....

- competence in an industries, start from a cooperation concrete mix design.With the prestige Institute Technology du Cambodge.

- The honor CEMKRETE (Thailand) with over 20 years’ experience in Concrete Admixture, Additive and Water Proofing products.

- In the intensified competition, Beton Concrete Industries has set up Two (2) Batching Plants at ING CITY to cater for the project development and at present the 3rd Batching Plant is on standby for the Ring Road Three Project.

- Beton Concrete will continue in practicing environmental protection as well as responsibility in leading industrial development dedicating to build a well-known International Ready Mix Concrete producer to enhance our group profile to support the Construction Industries.

Our Core Competitiveness Intelligent Production

Focusing on cost saving for Our Clients, Beton Concrete Industries has implemented the setting up the On-Site Batching Plant. Thus, this is Intelligent Production whereby the followings can be achieved:

* Temperature Control

* Slump Control

* Production Control

* Quality Assured

* Transportation Control

* Ensured Order of Concrete and Delivery on Time

STRUCTURAL WORK & ROAD CONSTRUCTION

Assessment and improvement of asphalt properties

Determination of asphalt component quality and suitability (bitumen, aggregates also secondary)

Development of new road products, including rollpave and road materials

Assessment of damage to (overheated) asphalt

Laboratory testing of bitumen, including composition (PAH and rheology/viscosity)

Calculations of the CO2 footprints of semi-heated asphalts

Assessment/testing of expansion joints

Determination of the maintenance condition of existing roads, drawing up subsequent maintenance/repair plans

Service life predictions

Controls of road mixture designs and auditing/inspection of road product application

HEAVY MACHINERY/EQUIPMENT

1.Dumper 6x4

2.Water Truck

3.Fuel Truck

4.Cargo Truck

5.Wheel loader

6.Stationary Pump

7.Cement Tanker

8.Touring 15set

9.Dump Truck

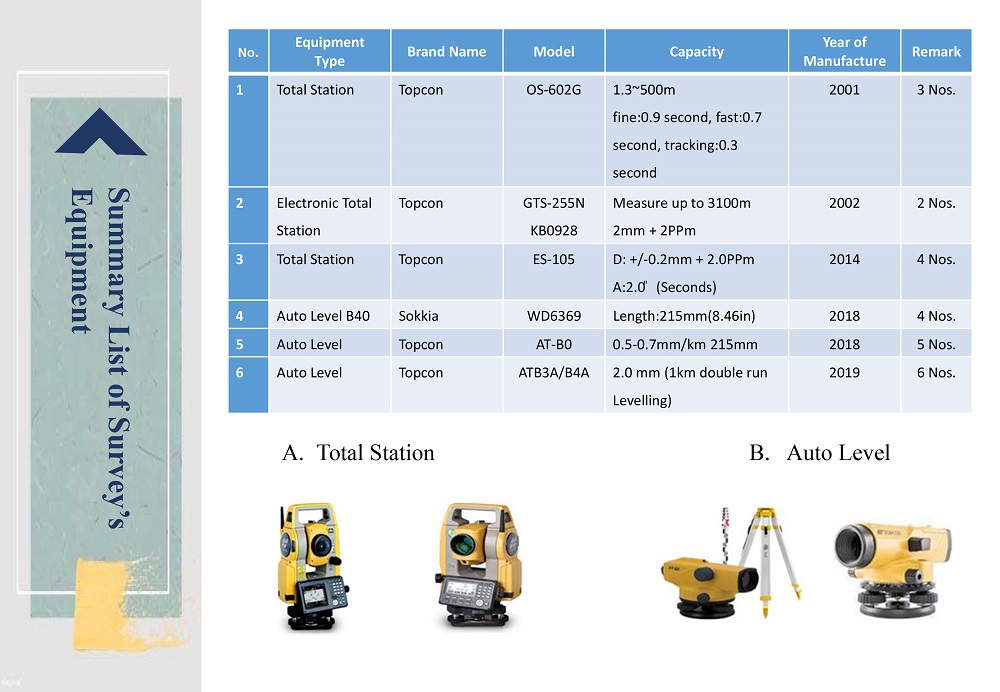

Survey’s Equipment

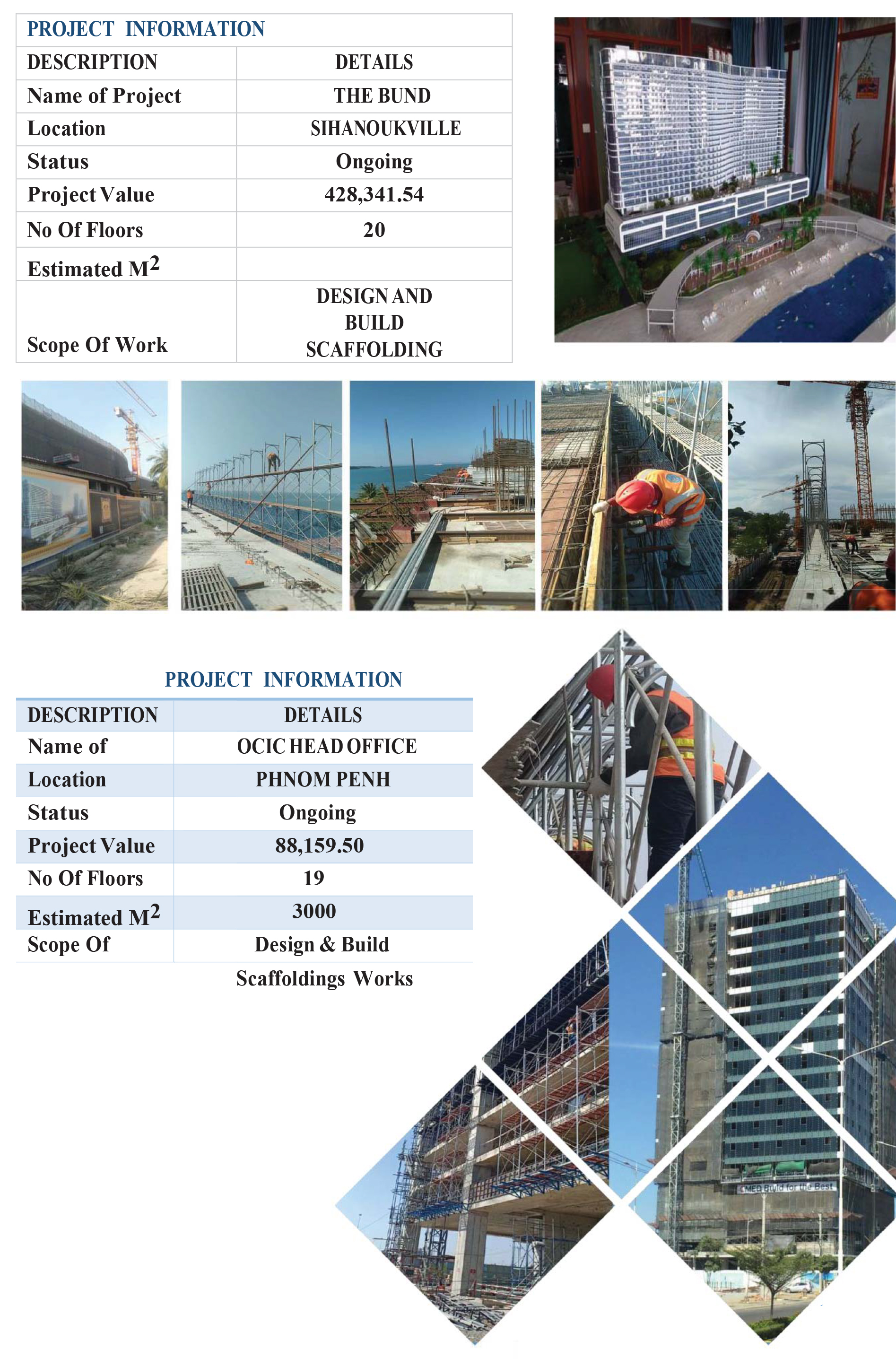

STEEL STRUCTURE (TOP-TAI SCAFFOLIDINGS)

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

MECHANICAL WORK

The construction, installation, replacement, repair, alteration, maintenance, testing or commissioning of a mechanical heating, cooling or ventilation system in a building, which is associated with the heating, cooling or ventilation of that of that building.

Scope:

- (a) The construction, installation, replacement, repair, alteration, maintenance, testing or commissioning of–

- (i) any valve, regulator, register, pipe, duct, flue, tank, heating or cooling pipe or surface, boiler, burner, coil, solid fuel heater or other item used in the system;

- (ii) Any single head split system;

- (iii) in relation to a cooling tower, any water pipe, valve, pump, automated dosing device or automated bleeding device or any other mechanical component that affects the cooling tower’s cooling water flow rate or wastewater disposal;

- (iv) Any fixed component used in a reticulation system for the supply or removal of medical gases from the gas source to a wall outlet;

- (v) Roof sheeting and flashing that is necessary for the purpose of any work.

- (b) Any design work that is incidental to or associated with any work.